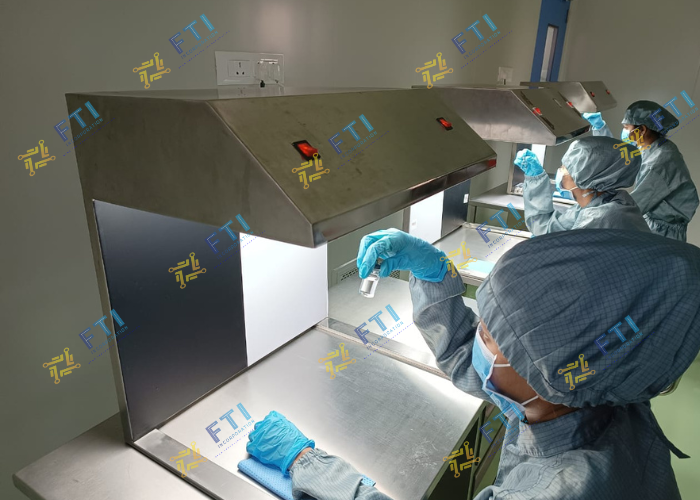

FTI is global pioneer in customized visual inspection challenge set supply for every kind of sterile product.

Indian firm incubated at National Forensic Sciences University (Institute of National Importance), Gandhinagar campus. We are focused on technological development and rapidly translating technologies from lab to commercial scale. With a deep industry expertise, our products and services are addressing the most advanced and uncommon segments of Pharmaceutical sector, Core Forensics. Forensic Technological Innovation is a Department of Industrial Policy and Promotion (DIPP), Ministry of Commerce and Industry, Government of India recognized company.

FTI Incorporation (Forensic Technological Innovation) is an Indian firm incubated at National Forensic Sciences University, Gandhinagar campus, focusing on technological development and deep industry expertise to achieve practical results with real impact in the field of Pharmacy, Forensics. This is a spin-off firm from NFSU research labs for transferring academic and industry collaborative research of NFSU into products for the industries. Forensic Technological Innovation Incorporation was founded by National Forensic Sciences University's research team consisting of qualified doctorates and domain experienced people in Pharma, Chemistry and Allied Forensics.

Satisfied Clients Globally

Member team of Experts in Contamination Investigation and Knapp Kit

Types of Injectable Packaging Material converted to Knapp Kits

Years of Expertise

The Knapp Test Kit is used for visual inspection and evaluation of weld quality, particularly in field conditions. It helps inspectors assess surface discontinuities like cracks, porosity, undercut, and weld bead size. It is a non-destructive testing (NDT) tool designed to ensure welds meet visual inspection standards.

A standard Knapp Test Kit usually includes: Weld gauges (for measuring weld size, undercut, etc.) Magnifying glass or loupe (for close inspection) Flashlight or penlight (to enhance visibility) Mirror with handle (for viewing hidden or hard-to-reach areas) Cleaning tools (wire brush, scraper) Inspection report forms and a carrying case

While the tools themselves are straightforward, proper training is recommended for accurate and standardized inspection. Visual inspectors should be familiar with applicable codes and standards to correctly interpret results and ensure compliance with weld quality requirements.

CCIT Challenge Sets—sometimes called challenge kits—are designed with engineered defects or leak pathways in container closure systems. They play a critical role in validating that CCIT methodologies (like vacuum decay, helium leak detection, pressure decay) can reliably detect even minimal or realistic defects that could compromise sterility. These kits help ensure that testing systems are sufficiently sensitive and reliable, supporting compliance with regulatory standards like FDA, EU GMP Annex 1, and USP guidelines.

These kits are employed during method development and validation in CCIT workflows. They provide both positive controls (with known defects) and negative controls (intact samples), enabling verification of a test method’s capability to detect critical defect thresholds. This validates that the equipment and methodology can meet regulatory criteria under 21 CFR Parts 211 and 610, EU GMP Annex 1, and USP.

A standard CCIT Challenge Set generally includes: Positive and negative control samples with certified, known defects (e.g., micro-drilled caps, defective seals). Sample containers (such as vials, ampoules, or syringes) prepared to simulate real-world breaches. Accessories or fixtures to simulate leaks according to different testing methods. Documentation that includes defect classification, validation certificates, and compatibility details for various CCIT methods. These kits are typically compliant with FDA and GMP standards and are built for reusability and traceability.